EKO EXPORT S.A.

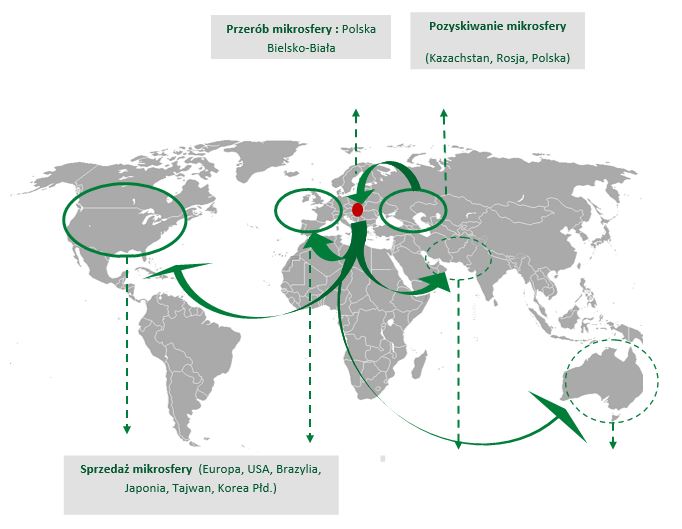

Specjalizuje się w pozyskiwaniu i sprzedaży mikrosfery. Spółka importuje surowiec głównie z Kazachstanu i Polski, gdzie po przetworzeniu w zakładzie produkcyjnym w Bielsku-Białej kieruje blisko 100% produkcji na eksport głównie do Europy i USA.

The leading specialization of the Company is the production of microspheres with the highest added value, refined, with parameters individually tailored to the specific requirements of customers, where the highest profitability is noted. As a result, the Company was able to build unique industry competences that will be extremely difficult for its competitors to achieve.

The key industry feature of EEX is fact that the production of microspheres is the Company's core activity and the only strategic development priority.

The concentration of core business on microspheres has resulted in the development of unique competitive advantages by the Company, which most of its market rivals do not have.

PRODUCT OFFER

QUALITY POLICY

PRODUCTION

MARKETING STRATEGY

At present, EEX is ranked among the world's leading companies in the microsphere industry. In Europe, EEX is the largest company of its kind; there is no other company in the region whose production capacity and level of technological advancement comes close to the parameters achieved by the Company.

Produced ceramic microspheres (silicon-alumina) are obtained, among others, during hard coal combustion, where they constitute one of the fly ash fractions. From the production cycle point of view, ceramic microspheres are therefore one of the types of combustion waste which are produced to the greatest extent by the energy sector based on traditional hard coal technologies. Procurement of raw material in the Eko Export S.A. industry is therefore based on cooperation with coal-fired power plants, for which microsphere is waste.

When coal is burnt at the edges of the high-temperature zone, the plastic slurry forms granules (bubbles) 0-0.5mm in diameter with gas inside. When the granules (microspheres) are transported with the slurry to the settling pond, they float to the water surface.

The traditional way of obtaining microspheres is to fish them out of the lagoon (sedimentation pond) and direct them to a dripping chamber made of tarpaulin, thus losing excess water. After long enough seasoning, when water content drops to about 20%, microspheres are packed into polypropylene bags and in this form sold for further processing.

EEX owns a unique patented technology for the recovery of microsphere from the water-ash directly from the pipes discharging the sludge produced after burning coal at the power plant in Nur-Sultan - the capital of Kazakhstan.. This line allows the recovery of almost all (about 95%) of the microsphere produced at the power plant throughout the year. The raw material obtained is characterized by excellent physical and chemical parameters of unprecedented purity on the market. The microsphere is obtained before it enters the lagoon (sedimentary pond), so it is free of any mineral impurities that are present in large quantities in lagoons. In comparison, with traditional pumped fishing from sediment ponds, only up to 20% of the microsphere can be collected, and the process is limited to the warm season as the sediment ponds freeze during the winter.

The activity of the Factory brings very beneficial ecological effects in the form of almost complete reduction of harmful waste generated in the power plant.

Microspheres in waste, i.e. the so-called spherical hollow grains with a tight, glassy coating, constitute from 1% to 3% of the total waste mass. Due to their structure, they have special properties with a significant negative impact on the environment. The bulk density of spherical grains is lower than the density of water, which causes them to float to the surface of settling ponds during hydraulic storage, forming the so-called "dross" several dozen or even several dozen centimeters thick. This dross dries out quickly and then the grains are carried away by the wind and carried away for considerable distances.

The microsphere extraction line itself has a neutral impact on the environment, as it does not use harmful raw materials or components.

High operating efficiency and quality of the obtained raw material make EEX technology innovative on a global scale, thus providing a significant, long-term competitive advantage over companies operating in the industry from all over the world.

EEX's business activity covers the full value chain in the microsphere industry. This means that the Company's expertise covers all operational phases - from the acquisition of raw material to the delivery of the finished product to final customers:

|

Operating phase |

Method of organisation |

|

Acquisition of microspheres |

Due to technological conditions (appropriate coal combustion processes), the main source of microsphere for further processing by the Company are power companies from Kazakhstan, Poland or Russia. |

|

Processing of Microspheres |

Production of the final product, including microsphere processing, refining and packaging is carried out in the largest European microsphere plant located in Poland (Bielsko-Biała). |

|

Sale of microspheres |

The sale of microspheres is carried out by EEX in parallel through two distribution channels: - through global intermediaries specialized in trading materials for industry - directly to final customers. |

EEX operates in a very innovative industry.Microsphere, in the production of which the Company specializes, is a modern industrial material with multiple applications in industry. It is constantly undergoing intensive research and development, thanks to which the spectrum of microsphere applications is systematically expanding. Therefore, the market on which EEX operates belongs to the group of emerging markets with very high growth potential.

PROENVIRONMENTAL

An additional stimulus for the microsphere market development is the fact that it is a pro-ecological product.Production of microspheres is a form of utilizing some of the most troublesome post-industrial waste generated during combustion of hard coal. Microsphere, as one of the fractions of volatile waste, is on the list of waste recommended for industrial use in the EU, and its management has been classified as environmentally friendly "clean technology". Therefore, the development of microsphere technology will also be stimulated by the environmental policy instruments of the energy sector.

Kadra zarządzająca

ZARZĄD

Jacek Dziedzic – President of the Board

Jacek Dziedzic is a co-founder of EKO EXPORT and has been holding the position of the President of the Board since the company was established. Managerial skills supported by his ong-term experience are combined with in-depth technical knowledge of microsphere production and personal contacts among the company's eastern suppliers.

Jacek Dziedzic has a higher education. He graduated from the Technical University of Lodz, Faculty of Textile, Mechanical Fiber Technology.

Przebieg kariery zawodowej:

- 1992 – 1998 – Kart – Graf S.C. z siedzibą w Bielsku-Białej – współwłaściciel,

- od 1996 roku – Jeans&Ginos z siedzibą w Bielsku-Białej – właściciel,

- 1999 – 2008 – EKO EXPORT Sp. z o.o. z siedzibą w Bielsku-Białej – Prezes Zarządu,

- od 2008 roku – EKO EXPORT S.A. z siedzibą w Bielsku-Białej – Prezes Zarządu,

- 2000 – 2002 – Videowall Polska S.A. z siedzibą w Bielsku-Białej – główny specjalista ds. inwestycji,

- od 2003 do 2009 – Dazi Investment S.A. z siedzibą w Bielsku-Białej – Prokurent.

Zbigniew Bokun – Director of Business Development

Co-founder of EKO EXPORT since 2003 involved in business development of the company. European pioneer in production of refined microspheres. In the 80's he developed technology of microsphere refinement allowing for significant reduction of production costs. In the 90's he was responsible for building Lang's sales network in Austria and Germany.

Zbigniew Bokun holds an incomplete higher education. He started studies at the Silesian University of Technology in Gliwice, Faculty of Sanitary Engineering.

Przebieg kariery zawodowej:

- 1968 – 1978 – działalność gospodarcza pod firmą Wytwórnia Prefabrykatów Budowlanych w Bielsku-Białej,

- 1978 – 1982 – Przedsiębiorstwo Polonijno-Zagraniczne „Konsuprod” z siedzibą w Bielsku-Białej jako Dyrektor Oddziału,

- 1983 – 1992 – Przedsiębiorstwo Zagraniczne „Labo – Lang” GmbH z siedzibą w Bielsku-Białej jako Pełnomocnik,

- 1992 – 1994 – „Labo Holding” Sp. z o.o. z siedzibą w Bielsku-Białej jako Prezes Zarządu,

- 1992 – 1994 – TU Fortuna z siedzibą w Bielsku-Białej jako członek Rady Nadzorczej,

- 1994 – 2003 – „Labo Holding Eko” Sp. z o.o. z siedzibą w Bielsku-Białej jako specjalista ds. marketingu i sprzedaży,

- 1994 – 2000 – VIENA LEAS INTERNATIONAL SA w Bielsku-Białej jako członek Rady Nadzorczej,

- 2001 – 2003 – Videowall S.A. z siedzibą w Pszczynie jako członek Rady Nadzorczej,

- od 2002 – „Labo Holding Eko” Sp. z o.o. jako członek Rady Nadzorczej,

- od 2003 roku – EKO EXPORT S.A. z siedzibą w Bielsku-Białej jako Dyrektor ds. Rozwoju Biznesu,

- 2003 – 2008 Dazi Investment S.A. z siedzibą w Bielsku-Białej jako członek Rady Nadzorczej,

- od 2008 roku – EKO EXPORT S.A. z siedzibą w Bielsku-Białej jako Prokurent,

- od 2008 roku – Dazi Investment S.A. z siedzibą w Bielsku-Białej jako Prezes Zarządu.

SUPERVISORY BOARD

Marek Kwiatek – Chairman of the Supervisory Board

Mr Marek Kwiatek is a graduate of the Faculty of Management at the University of Economics in Katowice.

He gained experience in financial institutions and manufacturing companies. He started his professional career in 1995 at Huta Ferrum S.A. in Katowice. There he was a specialist for controlling and budgeting. His tasks included analysis of financial statements, preparing business plans and budgets. Since 2007 he was a Financial Director in Murapol S.A. He supported the Management Board in decision-making processes aimed at achieving specific business objectives and the Company's strategy and, among others, supervised the implementation of IAS-compliant financial statements. Since 2008, he has been working for Zakłady Mechaniczne BUMAR where, initially, he was a Member of the Management Board for Financial Affairs of Bumar-Łabędy S.A. (in 2008-2011), and then he became the President of the Management Board of Bumar-Mikulczyce S.A. (years 2011-2016). In 2016-2017 he served as the President of the Management Board of Gliwice Sports Club "Piast" S.A. supervising the formation and implementation of the company's business strategy.

Mr. Marek Kwiatek has many years of experience as the Chairman of the Supervisory Board - he performed this function in 2009-2013 in Kuźnia Łabędy Sp. z o.o. and in 2009-2011 in Zakłady Mechaniczne Bumar-Mikulczyce S.A.

Mr. Marek Kwiatek is a member of the Supervisory Board fulfilling the criterion of independence specified in principle II.Z.4. of "Best Practices of WSE Listed Companies 2016".

Igor Bokun – Vice Chairman of the Supervisory Board

Igor Bokun has a higher education. He graduated from the Stanisław Staszic AGH University of Science and Technology in Kraków, Faculty of Electrical Engineering, Automatics and Electronics, majoring in Computer Science.

Janusz Hańderek Członek Rady Nadzorczej – Secretary

Mr. Janusz Hańderek holds a Master of Law degree from the Jagiellonian University in Kraków. Since 1992, he has continuously run his own law practice in Bielsko-Biała. For many years he has been a member of the Presidium of the Regional Council of Attorneys in Bielsko-Biała and a member of the Examination Committee for trainee attorneys of the Regional Council of Attorneys in Bielsko-Biała in the area of business law.

Apart from a broad legal practice in the scope of civil and criminal law, he is a legal advisor to a number of companies, i.e. District Tourist Management Team PTTK in Bielsko-Biała, Sanitary and Epidemiological Station in Żywiec, Greenline sp. z o.o.

Mr. Janusz Hańderek is a member of the Supervisory Board meeting the criterion of independence specified in principle II.Z.4. of "Best Practices of WSE Listed Companies 2016".

Andrzej Hugiel – Member of the Supervisory Board

Mr. Andrzej Hugiel is a graduate of Sanitary Engineering Faculty of Silesian University of Technology in Gliwice. He started his professional career at Fabryka Samochodów Małolitrażowych and Zakład Remontowo-Budowlany FSM as a sanitary installations inspector and installations works manager. From 1975, he was a construction team manager at the Katowice Municipal Engineering Combine in Bielsko-Biała. In the years 1976-1989 he worked as an environmental protection inspector at the Environmental Research and Control Center and the Provincial Office in Bielsko-Biała. Since 1989 he worked in several companies dealing with environmental protection as an environmental protection specialist and deputy director for technical matters. Between 1994 and 2003 he ran his own business in the furniture industry. From 2006 to 2018 he was employed at DAZI Investment in an administrative position.

Mr. Andrzej Hugiel is a member of the Supervisory Board fulfilling the criterion of independence specified in principle II.Z.4. of "Good Practices of Companies Listed on WSE 2016"

Agnieszka Bokun – Member of the Supervisory Board

Agnieszka Bokun has completed secondary education. She graduated from A. Asnyk High School in Bielsko-Biała. She also completed EDV AUSBILDUNG SCHULE in Vienna, gaining qualifications of a Programmer.

Przebieg kariery zawodowej:

- 1990 – 1992 – działalność gospodarcza pod firmą Przedsiębiorstwo Handlowe RAGAZZI,

- 1994 – 2003 – VIENA LEAS INTERNATIONAL S.A. w Bielsku-Białej jako Członek Zarządu, Specjalisty ds. Leasingu,

- 1998 – 2001 – JEANS & GINOS jako przedstawiciel handlowy,

- 2002 – 2003 – LABO HOLDING – EKO Sp. z o.o. jako specjalista ds. Leasingu,

- od 2003 roku – EKO EXPORT S.A. z siedzibą w Bielsku-Białej jako specjalista ds. handlu i eksportu,

- od 2003 roku – Dazi Investment S.A. z siedzibą w Bielsku-Białej jako członek Rady Nadzorczej,

- od 2009 roku – Dazi Investment S.A. z siedzibą w Bielsku-Białej jako Doradca Zarządu,

- 2005 – 2010 – Dazi Management Sp. z o.o. z siedzibą w Bielsku-Białej – członek Rady Nadzorczej,

- od 2008 roku – EKO EXPORT S.A. z siedzibą w Bielsku-Białej jako Członek Rady Nadzorczej,

- od 2010 roku – Webhelpdesk Sp. z o.o. z siedzibą w Bielsku-Białej jako Prezes Zarządu.

Dywersyfikacja dostawców / klientów

Fabryka czwartej generacji w Kazahstanie Direct Microsphere Collection (DMC)

Założenie firmy przez rodzinę Bokun

Grant for working capital for Eko Export S.A.

The project is to support the entrepreneur to ensure financial liquidity and support current operations due to financial difficulties faced by the entrepreneur as a result of the COVID-19 outbreak. Financial assistance provided under Scheme No. SA.57015 (2020/N).

Project value: 226,914.12 PLN

EU co-financing of the project: 226 914,12 PLN

![]()

Innovative way of preparing mixtures of microspheres used in advanced technological processes

Development of an innovative product with very high mechanical strength based on microspheres:

The objective of the project is to develop a production technology and implement an innovative material called TitanSpheres, obtained from commercially available microspheres. The new product will meet stringent quality requirements, which will expand the possibilities of using microspheres in the mining industry. One of the basic requirements for commercial microspheres is their mechanical strength. Determination of mechanical strength of microspheres consists in subjecting them to pressure of 2.05 MPa for 15 minutes. The compressive strength of microspheres is measured as the proportion of water-lighter fraction expressed in mass percentage after the pressure test. Natural microspheres isolated from fly ash currently offered on the market have strength at the level of 35-48% m/m. The objective of the project is to develop a technology to produce a material called Titan Spheres, for which the proportion of the fraction lighter than water after a compression test will be >=60% m/m.

Obtaining an innovative material under the name TitanSpheres, characterized by unique physicochemical parameters will require conducting research work including: - analysis of grain, density, chemical and phase composition of available microsphere raw materials,

- determination of correlations between selected physicochemical parameters and grain, density, chemical and phase composition of available microsphere raw materials,

- development of the concept of a new technological process allowing production of an innovative material called TitanSpheres,

- optimization of parameters of the new technological process, which will allow to produce TitanSpheres in large quantities, while maintaining stable quality of the final product.

- optymalizację parametrów nowego procesu technologicznego, który pozwoli produkować TytanSpheres w dużych ilościach przy zachowaniu stabilnej jakości produktu końcowego.

The effect of the conducted research will be the concept of modification of the technological process of preparation and refinement of raw microsphere material, allowing to obtain a super strong material in terms of mechanical strength - TitanSpheres.

Budowa nowoczesnego transportu surowca oraz zakup wózka widłowego jako element unowocześnienia procesu produkcji mikrosfer

Konferencje, Forum

Mineral Recycling Forum 2016

Wykład: Cenospheres from fly ash: development and markets Erwin Grossman, Head of Sales, Mine Feuerfest GmbH, Germany

Notatka z konferencji

European business 17.06.2015

One man’s waste is another man’s gold – wersja angielska

Dla jednych ludzi odpady, a dla innych złoto.

Industrial Minerals 03.2015

Mixing up the cenospheres market – Eko Export to bring new capacity on-stream

Zawirowania na rynku mikrosfer – Eko Export uruchamia nowe możliwości

Puls Biznesu 01.04.2014

Giełdowa Spółka roku 2013, To nie spowolnienie to nowa rzeczywistość, Takich spółek nam potrzeba

Przetłumaczony fragment dot. Eko Export.

Konferencja

StockWatch.pl

Eko Export realizuje cztery projekty i kreśli plany na przyszłość.